Acoustic Emission (AE)

Acoustic Emission testing is used to detect and monitor the release of energy from materials under stress. This method helps identify cracks, leaks, and structural weaknesses in real time during operation.

LRUT / Guided Wave Testing

Long Range Ultrasonic Testing (LRUT) or Guided Wave is an efficient method to inspect pipelines over long distances without the need for full insulation removal. It detects corrosion, wall thinning, and other defects.

Magnetic Flux Leakage (MFL)

MFL inspection is widely used for detecting corrosion and pitting in storage tanks and pipelines. By analyzing magnetic field variations, we can identify areas with metal loss or damage.

UT Crawler

Ultrasonic Crawler is an automated inspection system that scans large surfaces such as storage tanks and vessels. It improves accuracy and efficiency while minimizing human risk during inspection.

Phased Array Ultrasonic Testing (PAUT)

PAUT provides advanced imaging to detect cracks, weld defects, and flaws with high precision. It offers faster coverage and detailed visualization compared to conventional ultrasonic testing.

Time of Flight Diffraction (ToFD)

ToFD is a highly accurate ultrasonic method used to detect and size defects in welds and structures. It is often applied in critical inspections due to its reliability and accuracy.

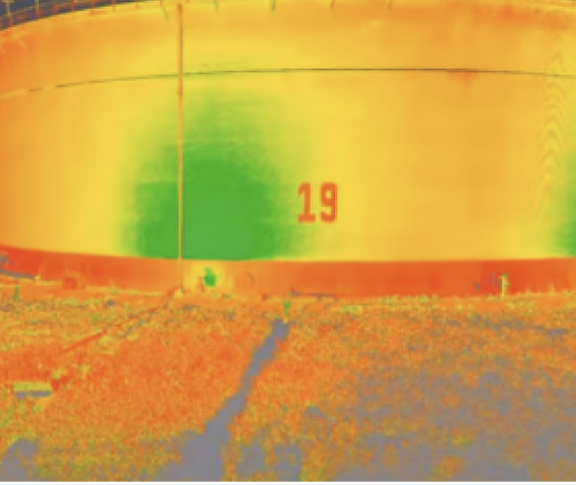

Infrared Thermography (IR)

IR Thermography uses thermal imaging to detect heat variations on equipment surfaces. It is effective in identifying insulation failures, electrical faults, and mechanical anomalies without physical contact.